Heavy duty impact beds boost conveyor efficiency

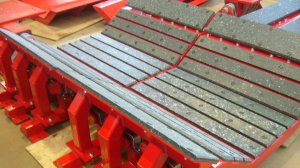

SMOOTH OPERATIONS The OST-Africa heavy duty impact beds ensure that a conveyor system operates smoothly at all times

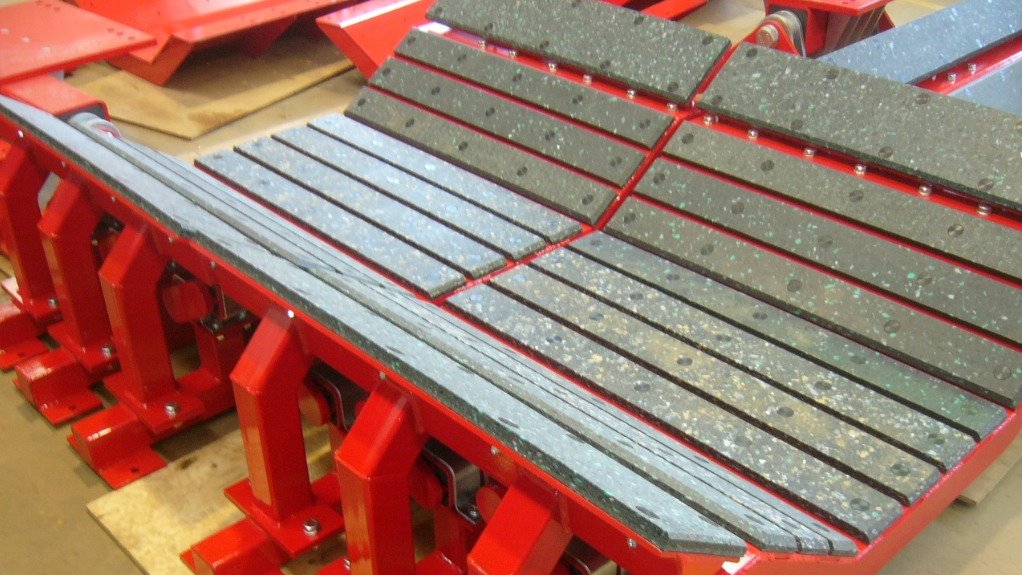

REDUCING WEAR The design of the OST-Africa impact beds helps to absorb and distribute the force of falling material more effectively, thus reducing wear and tear

In industries where efficient materials handling is critical, equipment supplier Oscillating Systems Technology Africa (OST-Africa) has developed a spillage system consisting of heavy duty impact beds that protect conveyor systems and boost productivity.

The advantages of OST-Africa’s spillage system, which protects the belt and conveyor truss from impact and vibration, are the improved belt tracking, efficient spillage control and reduced downtime of employing such a system, resulting in improved productivity.

“Conveyor systems play a critical role in many industries – including mining, quarrying, construction and bulk materials handling – by automating the process of moving large quantities of materials from one point to another,” explains OST-Africa marketing manager Chantelle Scheepers.

She further elaborates that streamlined conveying operations enhance efficiencies, increase production and enhance safety on site; however, the constant impact from heavy loads, sharp materials and debris, can damage the conveyor system, resulting in unnecessary downtime and costly repairs.

To combat this, Scheepers states that OST-Africa’s efficient spillage system presents important benefits over conventional systems, which are labour intensive, costly to operate and require additional equipment.

“The OST-Africa system encompasses various components that operate together to form one highly efficient system, with advantages that include simple installation, modular components for extended service life of the system, reduced maintenance and a low-cost solution to spillage problems,” she highlights.

Scheepers notes that the system does not require any additional support structures.

The OST-Africa spillage system consists of a dynamic heavy duty impact bed, the High Impact Torsion system, the skirt clamp and skirt wing, impact zone panels, duff feeders and the belt scraper range.

The OST-Africa heavy duty impact beds protect the conveyor belt from damage caused by heavy or abrasive loads, impact shocks, and wear and tear.

These robust impact beds are designed to enhance the efficiency of conveyors by absorbing and cushioning the load at critical points, especially where the conveyor belt encounters a build-up of materials, such as at a transfer point or chute.

The OST-Africa impact beds are specialised support structures placed underneath conveyor belts, primarily at the loading and unloading zones, to absorb the impact of bulk materials falling onto the conveyor belt.

These heavy duty impact beds, which are customisable to meet specific requirements, ensure that the conveyor system operates smoothly at all times and also extends the service life of the system.

Some key components of heavy duty impact beds include impact liners which are typically manufactured from high-impact, low-friction high density polyethylene material, known for strength and durability.

In addition to this, these liners are arranged in rows to provide continuous protection across the width of the conveyor.

This system provides reliable and cost- effective wear detection to indicate when replacement of a component is necessary.

A pan head screw is inserted into the liner and, as the high performance thermoplastic elastomer cap on the screw wears away, it acts as a clear indicator that the liners should be replaced.

Side panels, which are fixed and stationary, have an upward curve, to ensure optimal spillage control.

While the sides of the impact beds remain static and fixed in place, the centre section is designed to be more flexible, thereby helping to absorb and distribute the force of falling material more effectively, thus reducing wear and tear. The number of impact mounts needed depends on the maximum load the bed is expected to handle during operation.

All of OST-Africa’s products are built around the Neidhart system – a proven, high-performance design used globally in specialised materials handling applications.

The system consists of three main components: an outer tube, inner tube and four specially shaped round rubber pieces positioned between them.

When the inner tube rotates within the outer tube, it will twist the rubber, generating a torsional force, allowing the system to absorb energy and dampen shocks, providing effective protection against impact and overload.

The advantages of corrosion resistant Neidhart units include natural oscillation and vibration damping, as well as shock load capabilities and extended service life.

Most standard frames can be converted to suit Neidhart impact suspensions and mounting pitches are suited to fit existing stringers. This means that no special support structures are required when using standard conveyors.

OST-Africa’s materials handling, screen and transmission products, are supported by specialised design and installation teams, which will ensure these custom-built systems meet exact requirements in every application.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation